88

Fraunhofer Institute for Reliability and Microintegration IZM

Power Electronics at Fraunhofer IZM

IZM has all necessary expertise in the en-

tire development chain, from system de-

sign, packaging, thermal management,

electromagnetic compatibility, through to

reliability and damage analysis.

Electrical System & Circuit Design

Applications for power electronic compo-

nents are endless – in industrial drives, to

generate renewable energy, in transport

and more. The IZM is developing ground-

breaking solutions for demands such as:

•

High switching currents

•

High voltages

•

Very fast switching for SiC/GaN and

highspeed Si-devices

•

Mechanical stability

•

Strict EMC specifications

•

An extremely long lifetime

•

High reliability

Electromagnetic Compatibility

IZM is specialized in EMC and provides

consulting and research for all phases of

product development. Starting with basic

research into interference phenomena in

specific applications, we cover the entire

spectrum, including troubleshooting after

product delivery. We use in-house simu-

lation processes developed specifically for

frequent problems, as well as sophisticated

measurement series.

Thermal Management

The heat is dissipated from the chips

through various interfaces, thermal inter-

face materials, spreaders and substrates

before being released into the environ-

ment by a heat exchanger (cooler). All of

the specified points have to be optimized

to guarantee that the heat is removed

reliably and to meet the application’s

requirements.

Packaging

IZM has a wide area of packaging tech-

niques at its disposal:

•

Large-area solder joining; Ag sintering;

diffusion soldering/bonding

•

Heavy wire and ribbon bonding

•

Embedding technologies as well as

housing/encapsulation

•

X-ray and US microscopy, visual inspec-

tion and mechanic testing

Reliability

The damage behavior of materials and

components are carefully analyzed and

characterized in experiments; selected

material and geometry parameters can

be simulated (FEM). Technology-specif-

ic material properties are a particular fo-

cus of measurement technology at IZM.

Among other things, such properties are

the key extending the lifetime of a solder

joint or a wire bond, and for measures

that improve reliability.

Laboratories for power module and

packaging qualification

•

EMC-Lab

•

Thermal measurement and thermal/

mechanical simulation

•

Active and passive power cycling

•

Quality and reliability testing incl. com-

bined and accelerated lifetime tests

•

Material characterization: EBSD, FIB,

SEM, EDX, Nano-Indentation

Solar converter with embedded module,

Little Box Challenge

Embedded SiC-power module

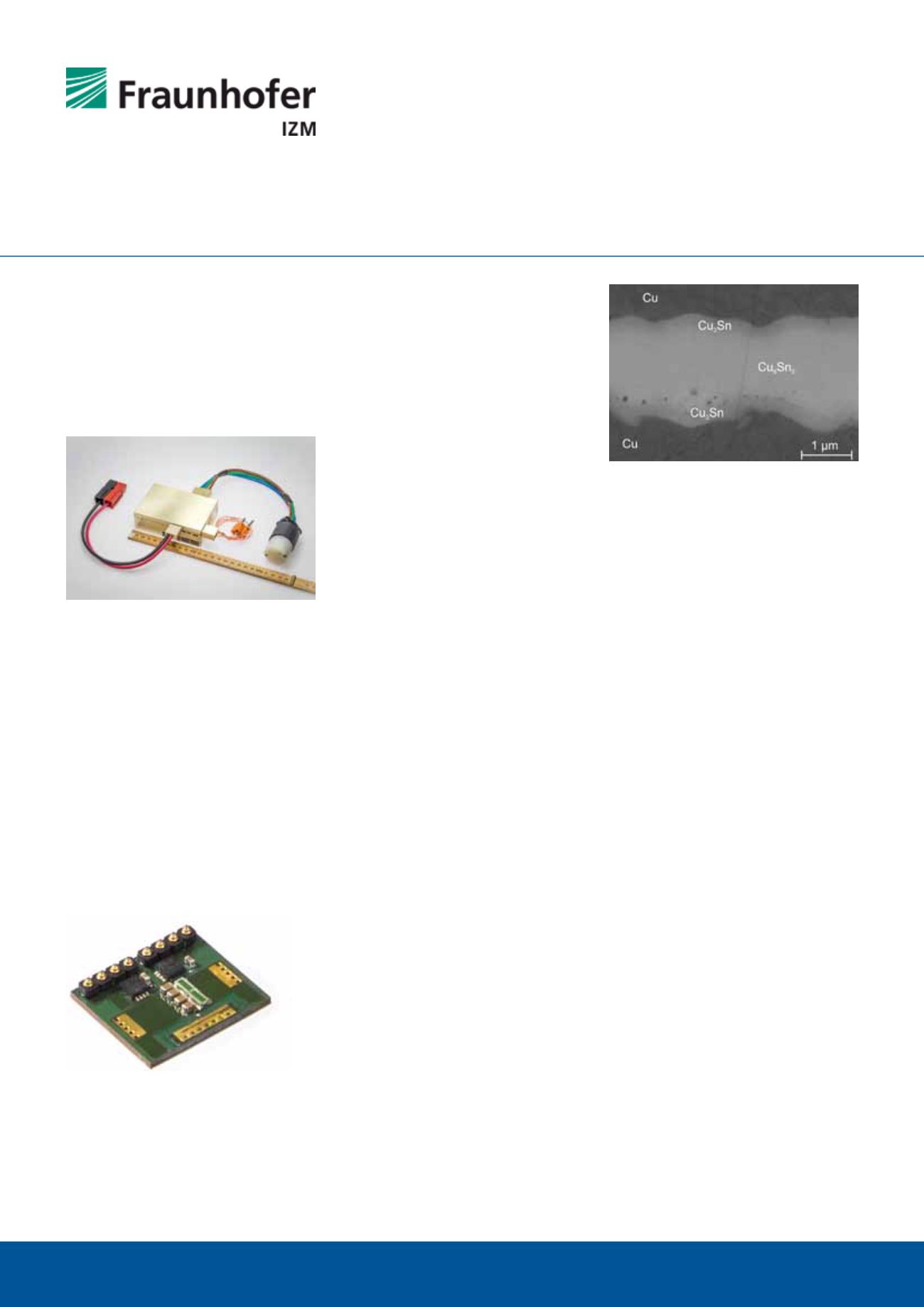

Diffusion bonded layer