117

FRAUNHOFER INSTITUTE FOR MICROSTRUCTURE OF MATERIALS AND SYSTEMS IMWS/

CENTER FOR APPLIED MICROSTRUCTURE DIAGNOSTICS CAM

About Fraunhofer IMWS/CAM

Fraunhofer IMWS/CAM is a leading ser-

vice provider for failure diagnostics and

materials assessment. Contract R & D

for industry in the area of semiconduc-

tor technologies, microelectronic com-

ponents, microsystems and nanostruc-

tured materials is our day-to-day business.

Fraunhofer CAM covers the entire work

flow from non-destructive defect locali-

zation over high precision target prepara-

tion to cutting edge nanoanalytics, sup-

plemented by micro-mechanical testing

and numerical simulation. In preparation

for future challenges, we do undertake

intense forefront research in cooperation

with international partners from academia

and industry. See

for further information.

Failure Diagnostics in Power

Electronics

Fraunhofer IMWS/CAM provides failure

analysis for power semiconductors,

including power ICs, MOS transistors,

IGBTs, diodes and sensors developed for

operation under standard and harsh envi-

ronment. In addition to Si-based systems,

we investigate and analyze the behavior

and performance characteristics of novel

SiC and GaN based devices including

related dielectrics, metallization layers

and contact systems.

Particular attention is paid to a fundamen-

tal understanding of interface material

properties and mechanisms relevant for

new interconnection and packaging

approaches. Current activities cover the

characterization of heavy wire bonding

materials, Ag-sintering, diffusion solder-

ing, new substrates and housing materials.

Fraunhofer CAM closely collaborates with

leading manufacturers of analysis and

testing equipment with explicit focus on

the development of innovative tools and

test methods for quality assessment and

failure analysis valuable for the electron-

ics industry.

Portfolio

•

Microstructure/failure analysis of power

semiconductors on wafer and chip level

(ICs, MOS transistors, IGBTs, diodes

based on Si, SiC and GaN) and of pack-

aged components and modules

(including high temperature operation

> 250°C)

•

Material characterization of high

temperature-stable metallization and

conducting systems

•

Characterization of interconnection

materials like heavy wire bonding

contacts/materials (e.g. Al, Cu, Al/Cu

clad wires/ribbons)

•

Characterization of encapsulation

and housing materials

•

Modeling and numerical simulation

of mechanical, thermal and thermo-

mechanical device and material

properties

•

Development of tools and methods

for failure diagnostics and quality

assessment specifically adapted to

power electronics

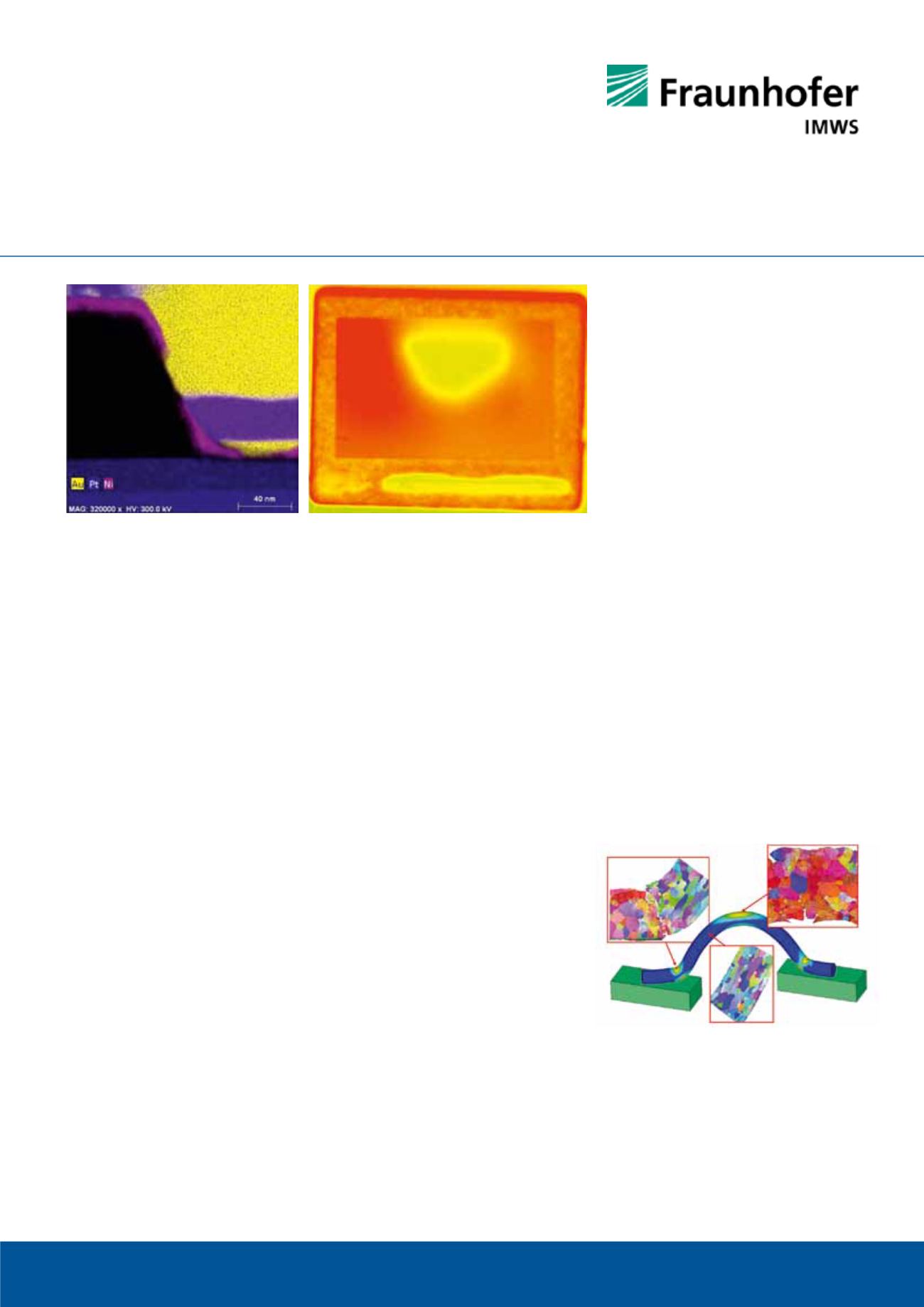

TEM EDS mapping of a GaN HEMT gate structure

Pulsed thermography of a defective Power MOSFET

device with interface delamination

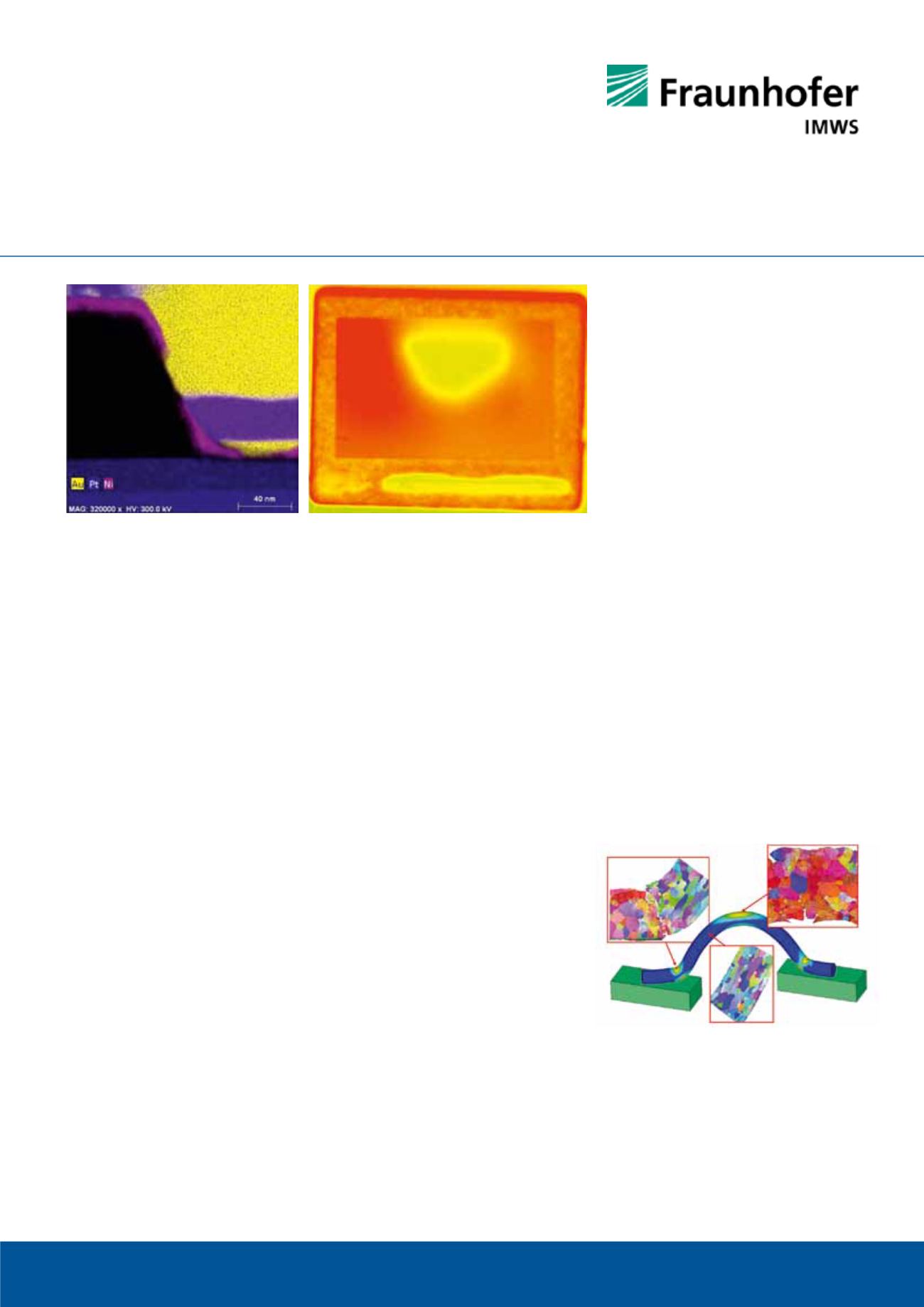

Finite Element model and grain structure characteri-

zation by Electron Backscattered Diffraction (EBSD)

for a low cycle fatigue analysis of heavy wire

bonding interconnects